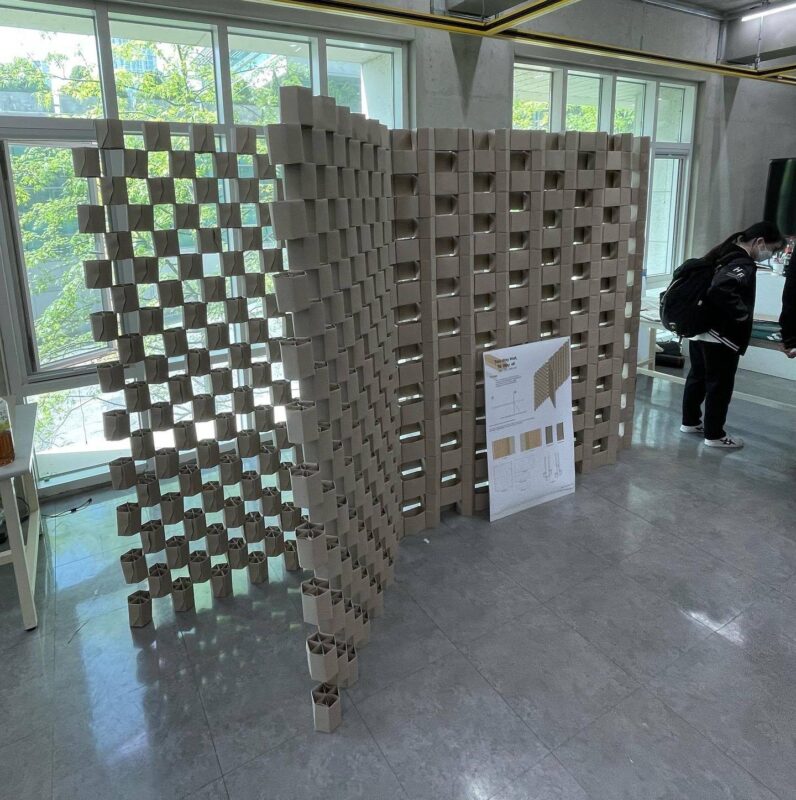

Tissue House

2024, Personal Work

Objet

>Woodwork

Inspired by an asymmetric gable roof, this tissue case was crafted by combining charred ash wood with stainless steel and finished with natural OSMO oil. A total of seven pieces were made, each given as a gift to people I am grateful to.

Tap the image to open it in full view.

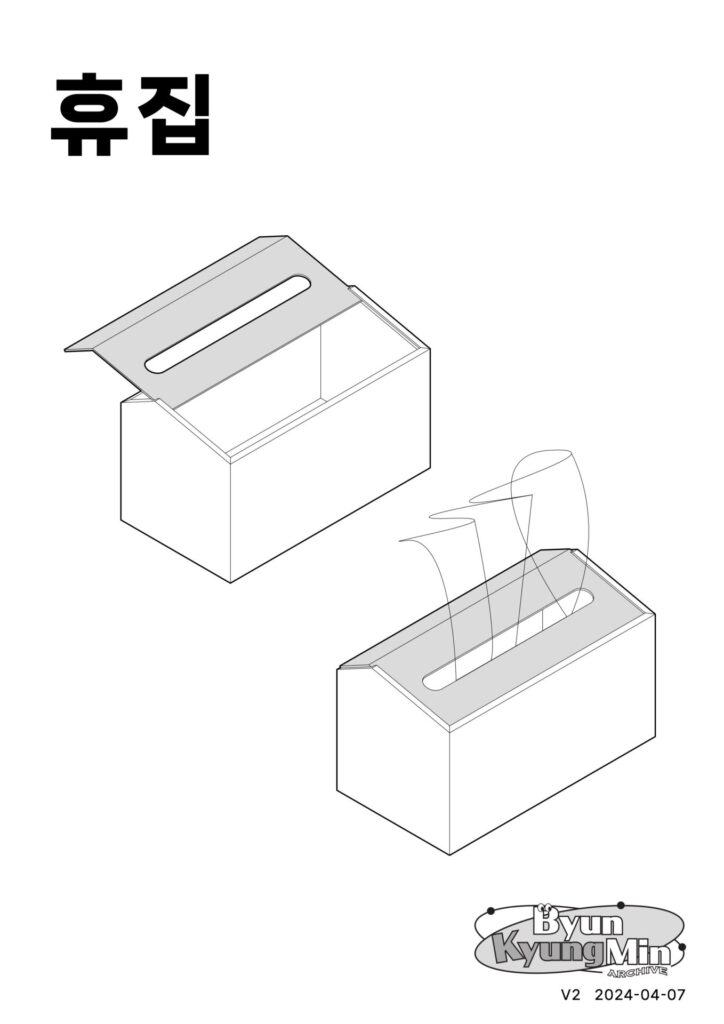

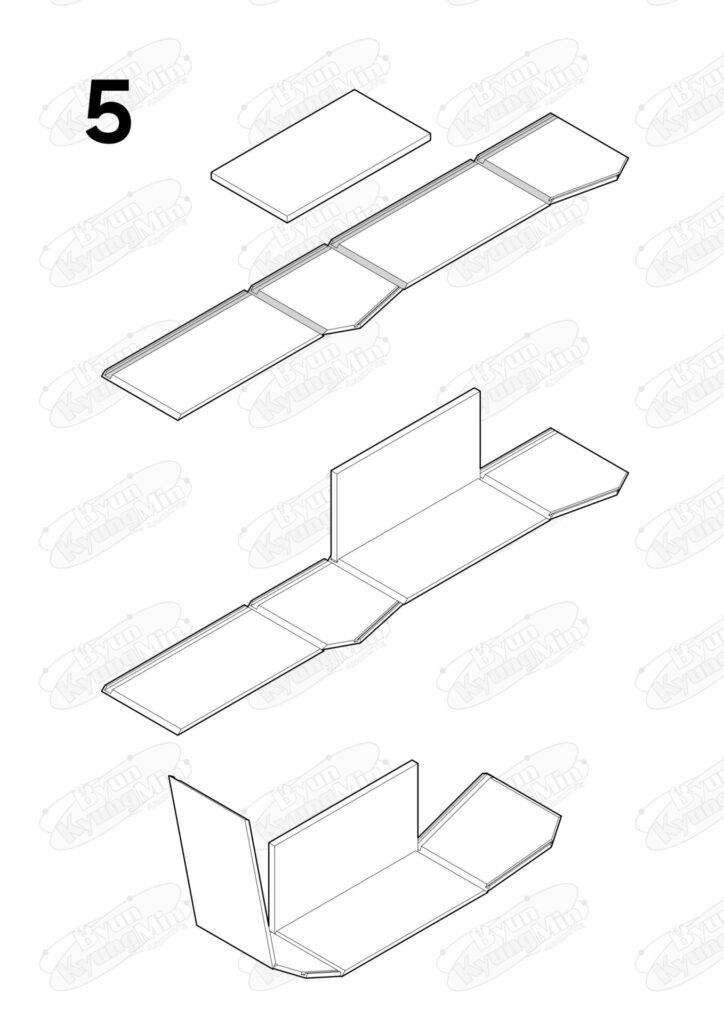

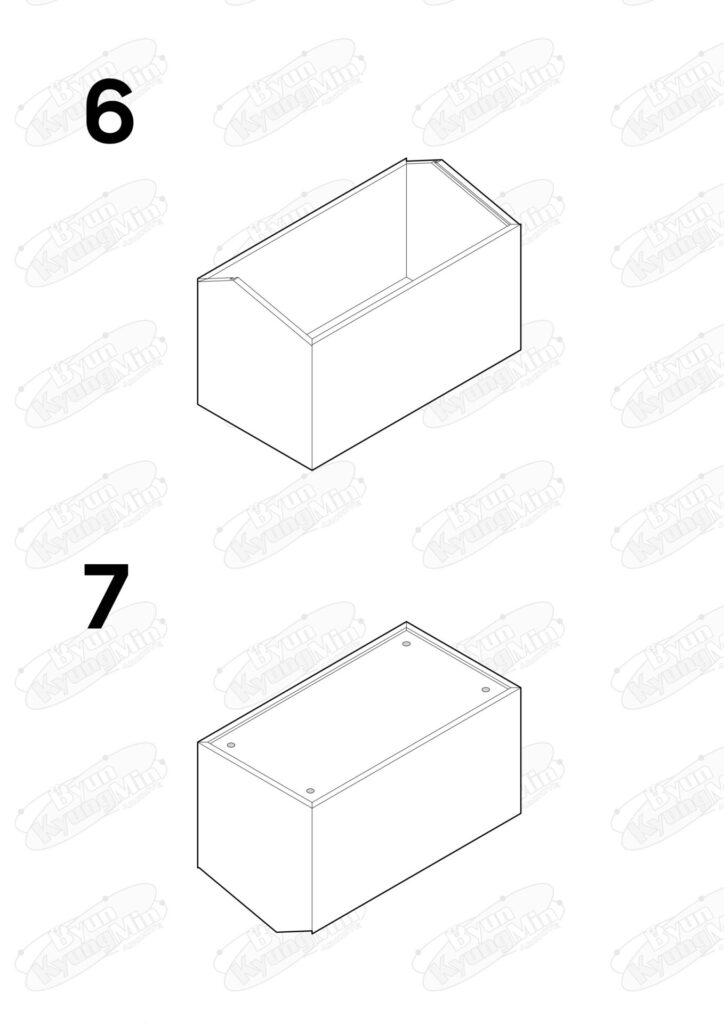

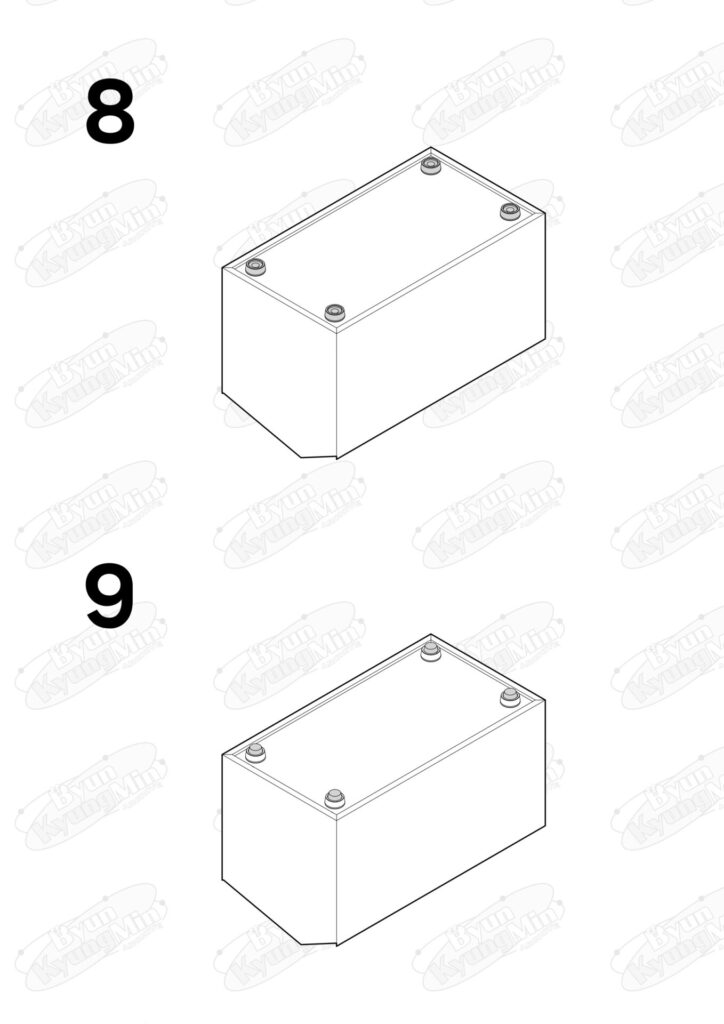

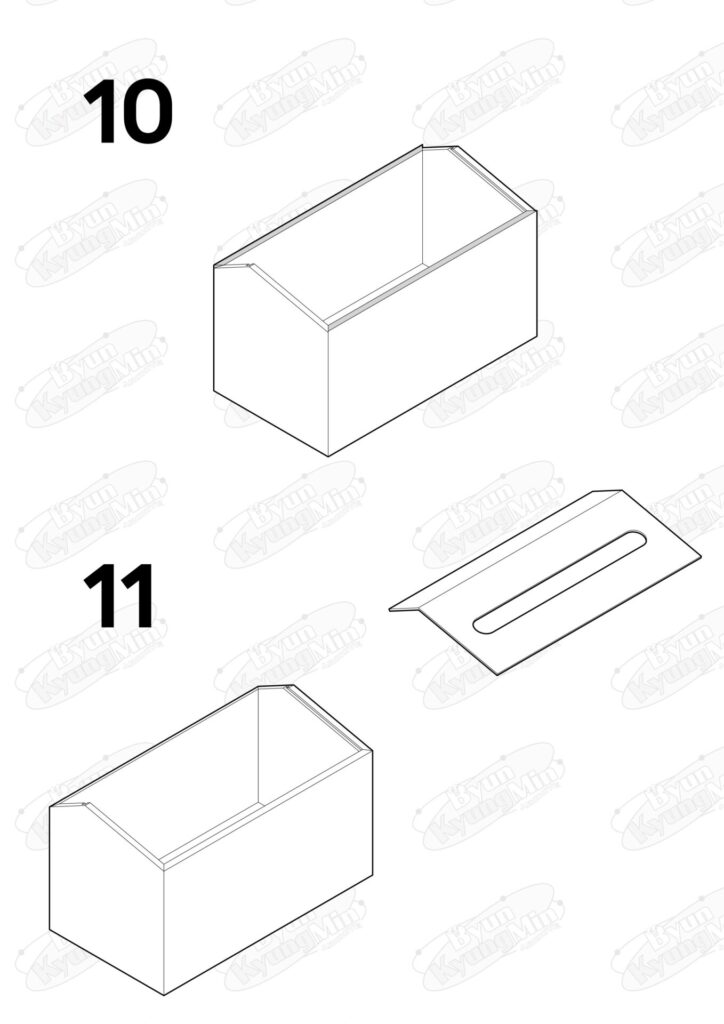

instructions made by my self

Behind

First attempt with charred ash. Did this in between long glue-up sessions for the end-grain cutting board.

Lots of clamps.

I’d wanted to try using metal for a long time, and finally got the chance.

Also the shop is not that far from my house.

Originally, the stainless steel was meant to add weight so tissues could be pulled out smoothly, but it was heavier than expected and tore the tissues. Even at only 2T thick, it was surprisingly solid and heavy.

Because it didn’t work as a tissue case, I had to revise the design.

Designed a branding iron logo and ordered it—cost about 80,000 KRW with a 130W soldering iron.

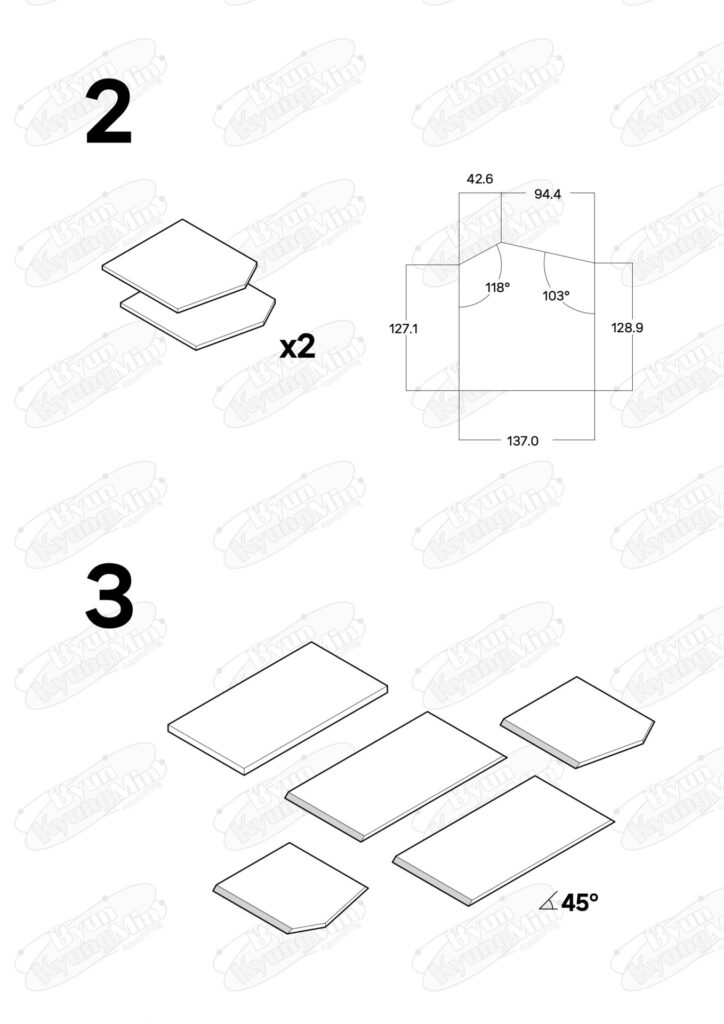

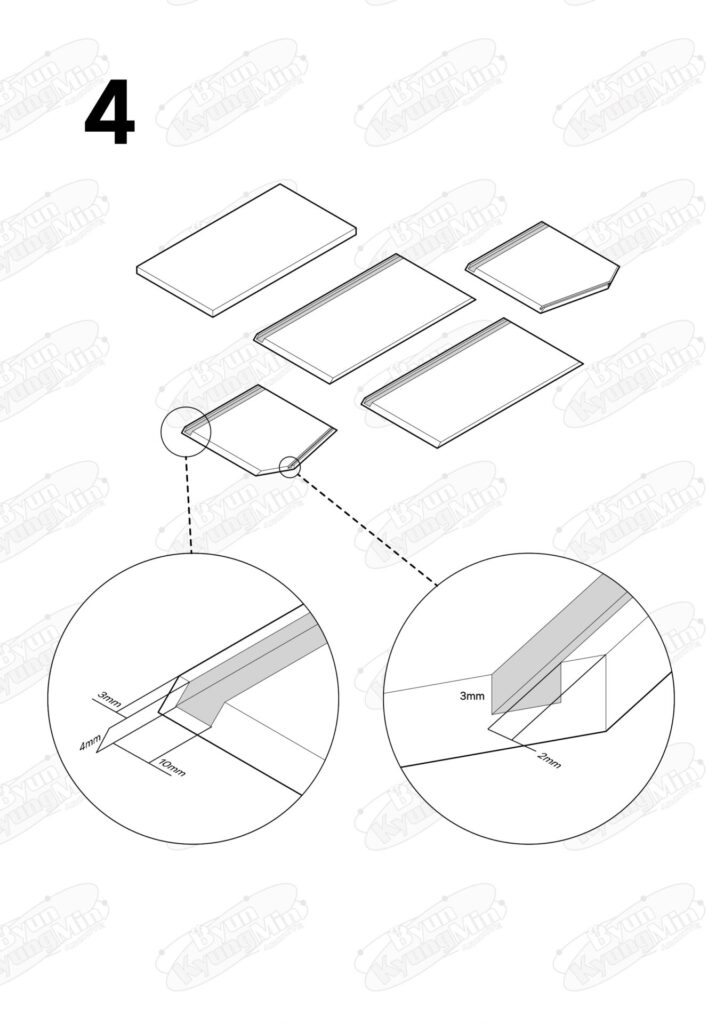

Sent off the revised design. Inspiration came from a house shape I noticed one day. This version included bending details.

While modeling, I realized: the simpler the design, the more time I spend rotating and reviewing it from every angle.

Making the instruction sheet. Disassembly is just the reverse of assembly.

Delivery day—an exciting moment. The stainless steel was 2T HL (hairline), meaning polished with straight-line finishing.

Tried stamping with the branding iron, but getting a clean result was tough. A vertical press tool, like a drill press, would make it much easier.

Building again with the revised design.

Added brass feet. These help reduce wobble from uneven surfaces, and washers can be added for fine adjustments.

Finished—ta-da!

View Other Works

All

Architecture

etc

Furniture

Objet