Tumble Up Plastics

2023, Team Work

Architecture

>Competitions

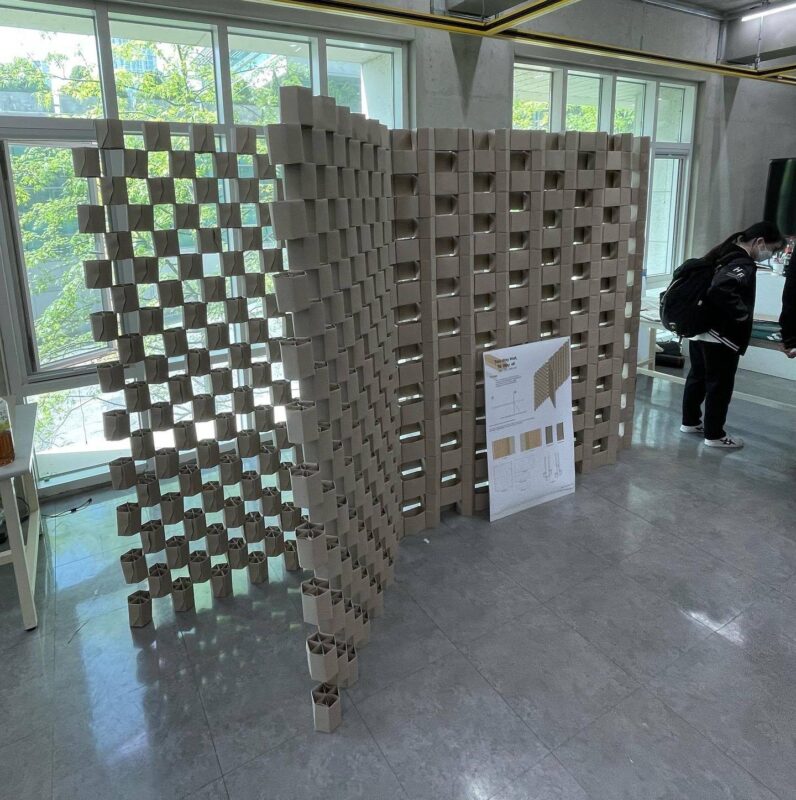

I participated in the 2023 UAUS Pavilion Exhibition, Design for Deconstruction, as a member of the Hanyang University team. The year’s theme questioned the wastefulness of materials discarded after serving a single purpose in architecture, seeking instead to assign them new roles and meanings. Our team approached the project with recycling as the starting point. Bottle caps collected from the local community were sorted by color, shredded into flakes, and transformed into recycled plastic panels. These panels were CNC-processed into three types of modules, which together formed the pavilion. After the exhibition, the same modules were repurposed as trash bins, returning to local communities to collect secondary waste and continue their cycle of use.

Tap the image to open it in full view.

All the photos taken by MinGi

@tumbleup.plastics

I was in charge of organizing and branding the posts of the tumbleplastics project.

Logos and Badges

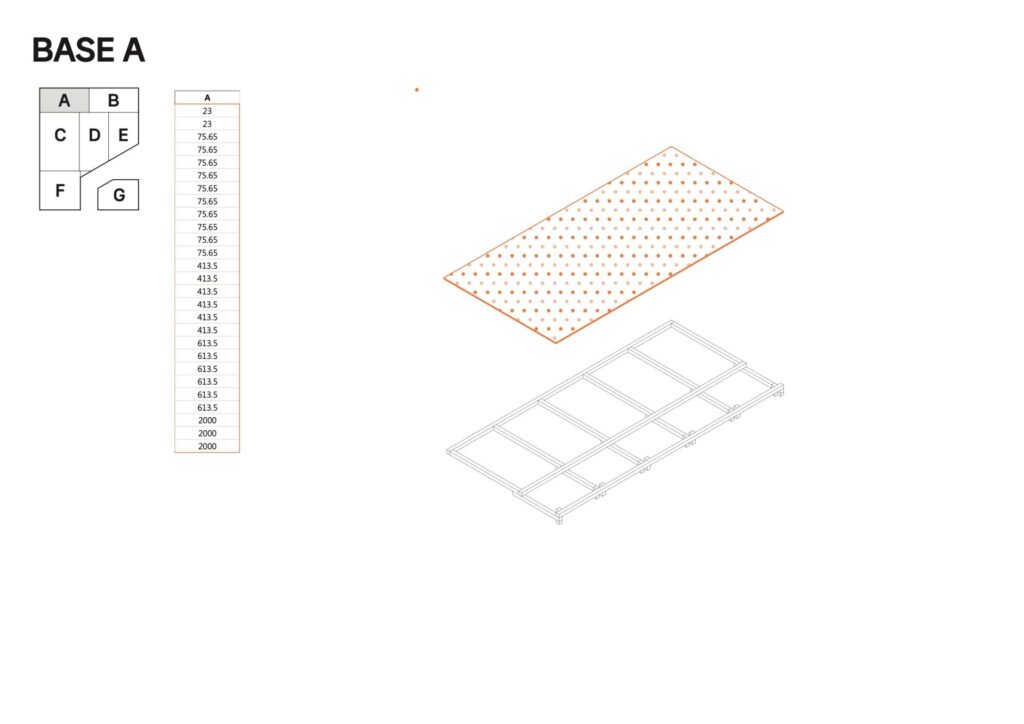

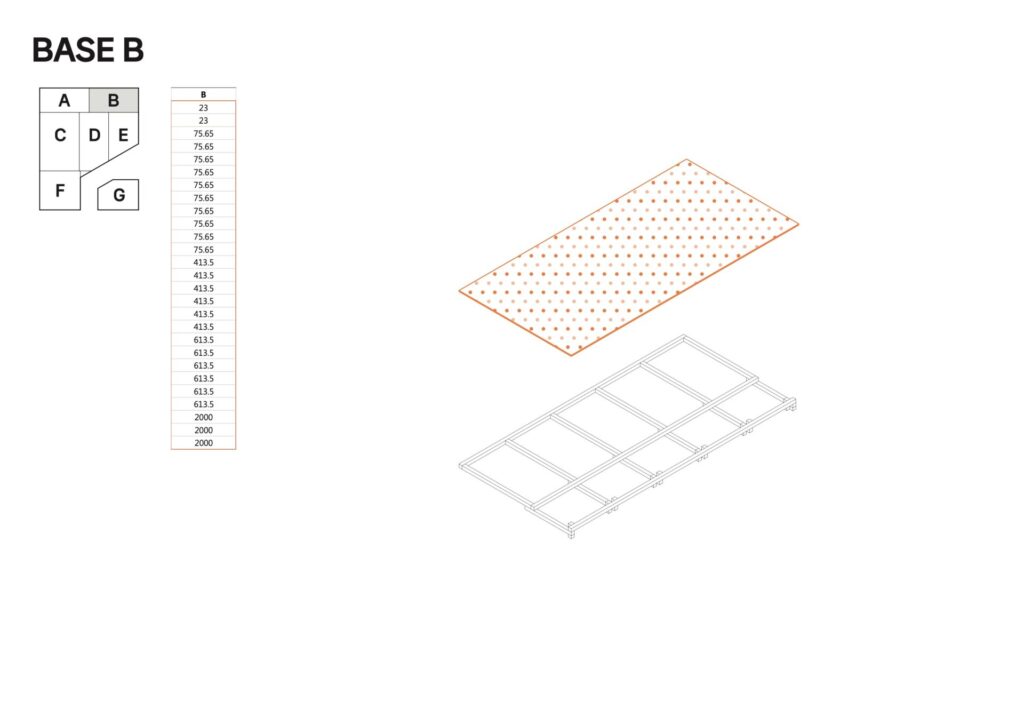

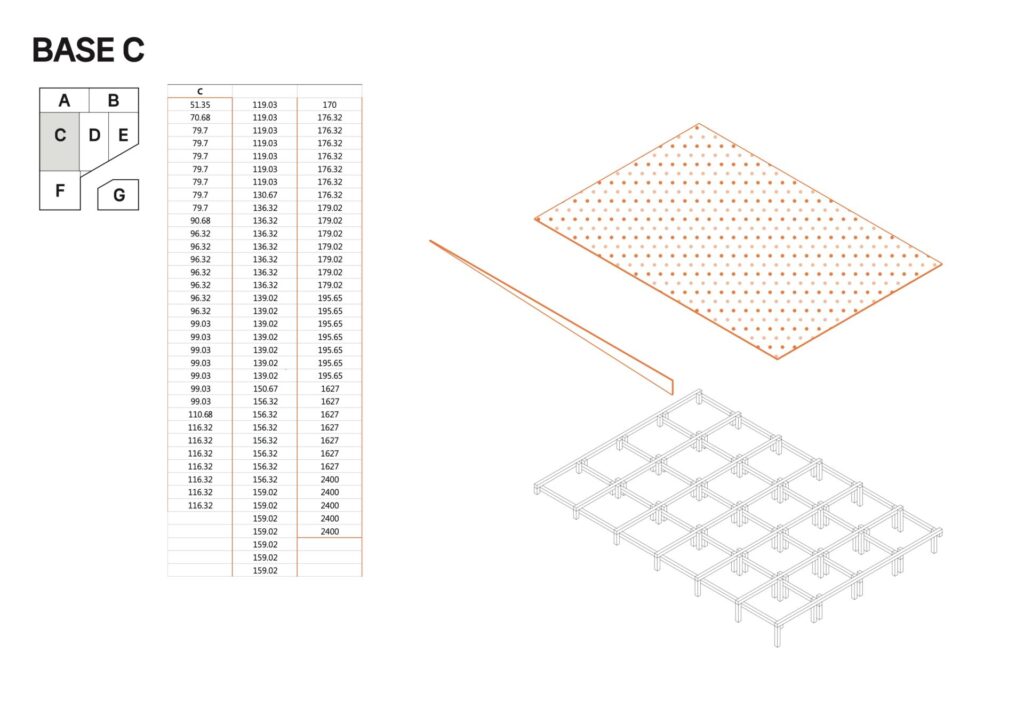

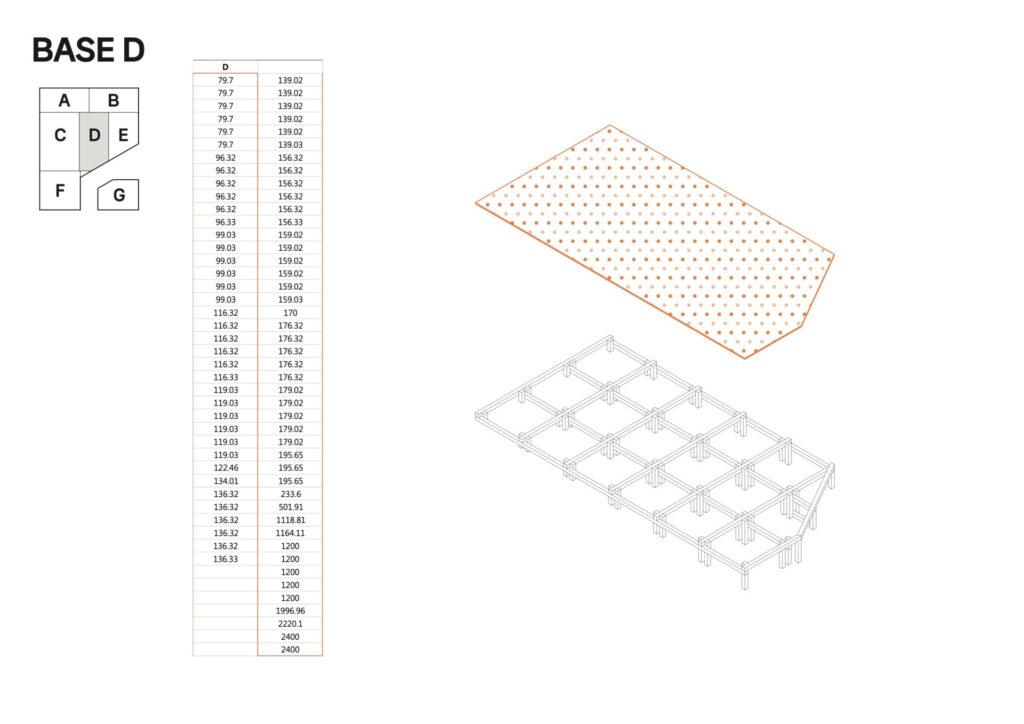

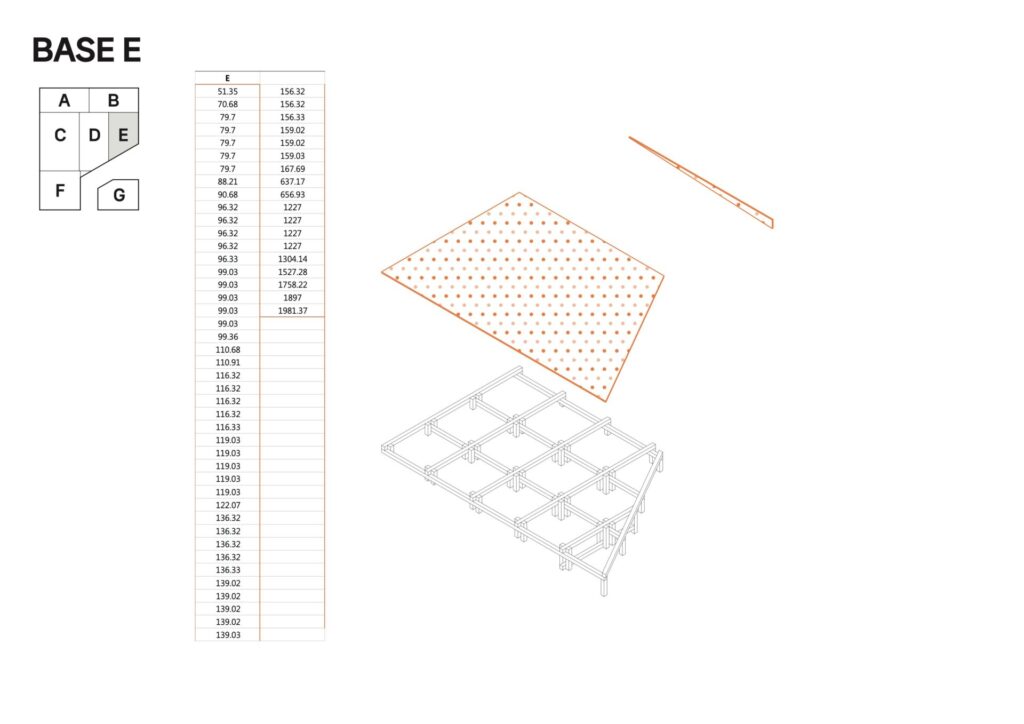

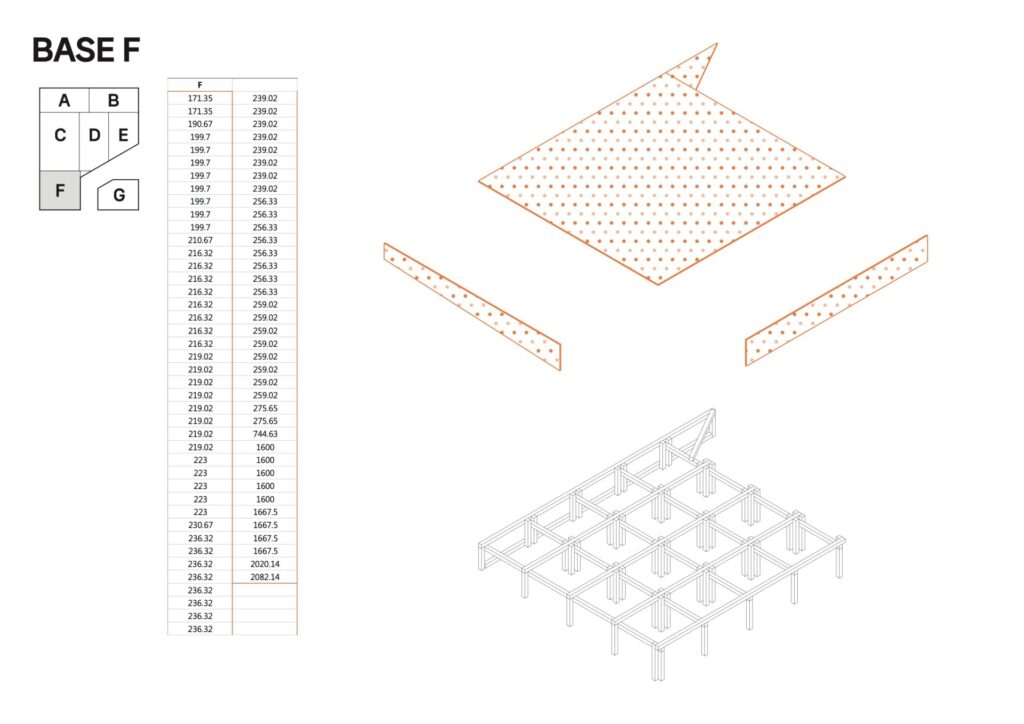

a reading table of the manufactured quantity of the base

A fleet production table with automation work using grashopper and python. The design was not done directly, but it was organized nicely.

Behind

On the day of the school’s internal competition. I only made a few diagrams the day before—our seniors did the rest.

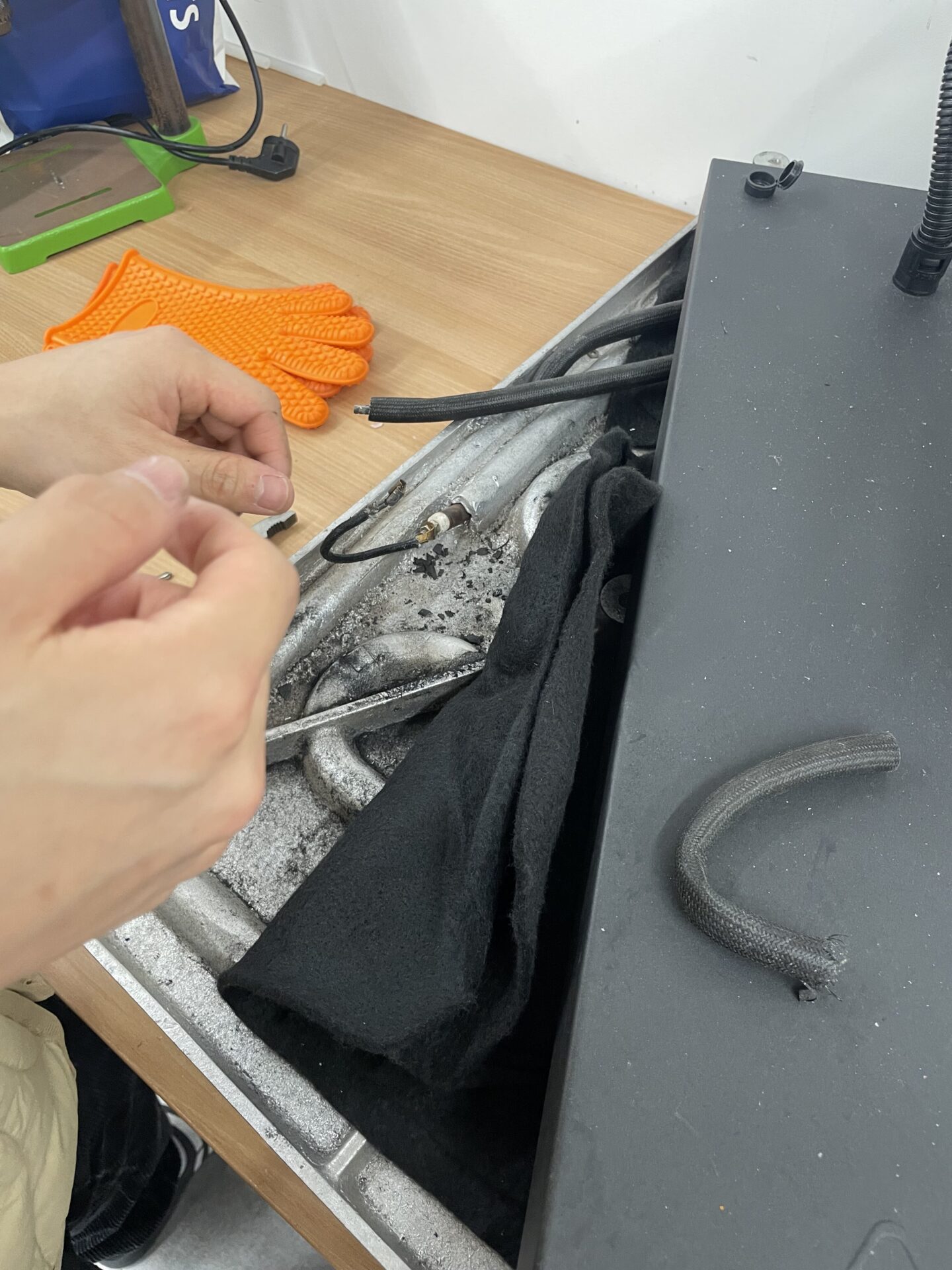

Really early studies on how to recycle bottle caps. We bought an oven secondhand and melted the caps.

The melted caps were poured into a makeshift mold to cool and harden. (Special appearance by Kyungyi’s shoes.)

Once cooled, we trimmed the edges and sanded them a bit. They looked beautiful—colors of plastic I’d never seen before.

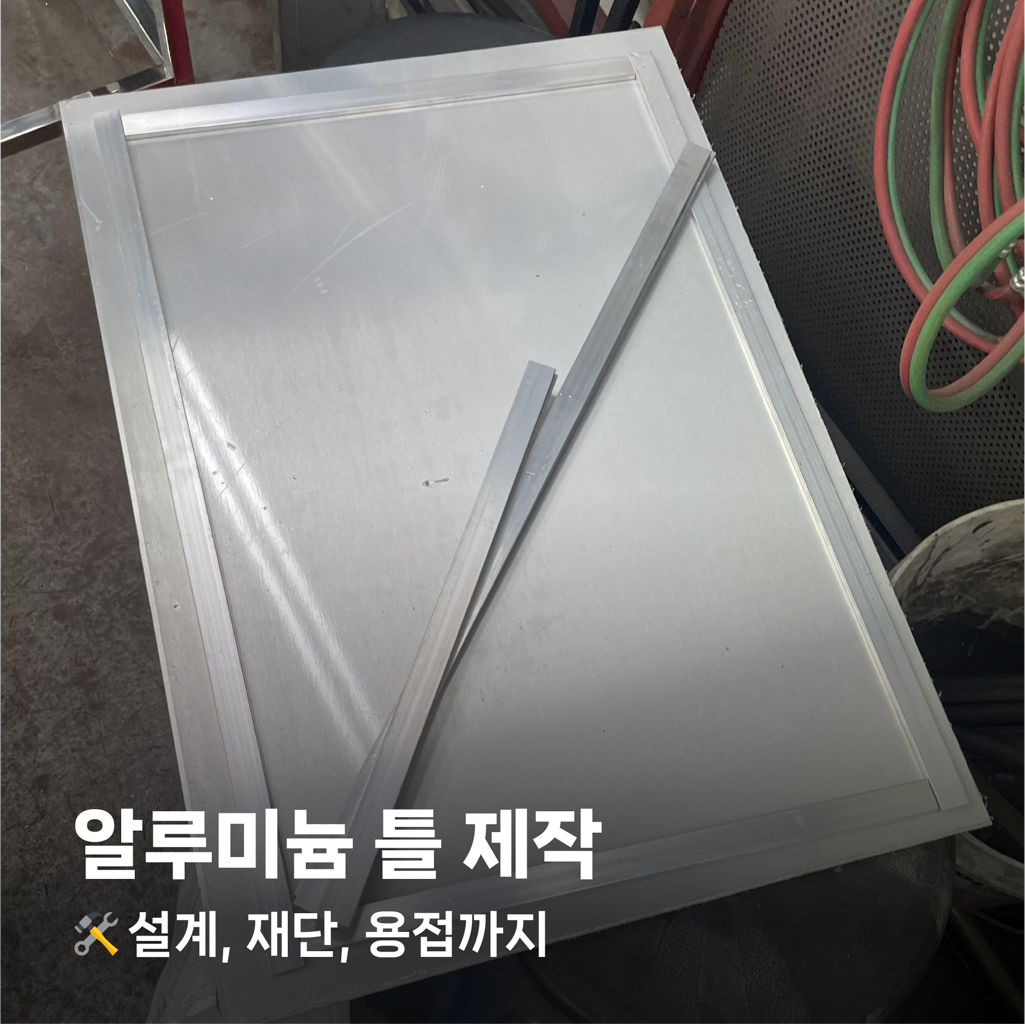

I picked up a new skill in Jongno: how to track down the exact metal materials I needed by going shop to shop, asking until I found them.

Who on earth drinks this much water?

On the way back from Seongsu with the ’19 seniors after buying plywood and timber. The weather was perfect.

After heat-pressing the plastic, it has to stay pressed while cooling to hold its shape—called cold pressing. We built the press with the steel frame from Jongno plus plywood and lumber we bought.

On the way to crush bottle caps.

My health is important… The mask I bought then is still serving me well in the workshop.

Running the CNC machine program. Similar to a 3D printer, it runs on G-code. Dozens of commands flash by every second.

The CNC-milled panels were divided into three modules, six pieces in total.

A comparison between the MDF trash bin mockup and the real CNC-milled piece.

In the middle of our busiest days, I experimented by milling a heart pattern. The seniors scolded me for it… (but it was kind of fun).

Nothing’s more fun than goofing around like that.

Scars of glory… I still have burn marks from then. Strangely, I kind of like them.

We ran a small print factory out of the 5th-floor maker room.

Test-assembling at school before heading out.

Photo of the pavilion outside the architecture building after completion. It was huge—an overwhelming moment.

We also filmed a making-of video.

With leftover scraps, I made these little pebble-like pieces. They looked surprisingly pretty.

Maybe no one complained about these because they were nice-looking?

Labels to help us assemble in the right order on-site.

The morning of departure for Seoul City Hall. Everything packed neatly into the truck.

Bring all the labels.

Inside a seminar room at Seoul City Hall. I looked around thinking, when will I ever get the chance to be here again?

A rainy day… At the start of docent duty it wasn’t raining, so I left my bag and kept chatting. In the background of the photo, my bag was soaking, and I lost a USB-C port on my laptop that day. Ha.

Scene of making the 1:10 scale model. The seniors set up a really efficient workflow. The finished model was displayed for several days at the Seoul Hall of Urbanism and Architecture.

The finished 1:10 model. I went home in the morning after an all-nighter, but the seniors stayed until the end to finish it. A moment that made me admire them again.

There’s a rule: if you win first place, you have to run UAUS the following year. We used to joke it’d be best to win second place—and that’s exactly what happened. Even happier.

The grand prize went to Hanyang University ERICA. Having gone to high school in Ansan, I feel oddly attached to ERICA. I even did volunteer teaching there a few times—I remember how big the campus was.

From here on, it’s about preparing for the Gwangju exhibition. Instead of the old mixed flakes in white+clear, we tried newly purchased transparent pellets. The colors came out gorgeous, with an even cleaner surface—stunning in the light.

We overworked the heat press so much that the fuse blew twice in a row. The first time, a technician fixed it. The second time, Mingi stepped up.

What happens if you run it without a fuse? Hehe.

Open up the breaker box~

Cutting off power to the whole room also stopped the printers that had been running for over ten hours. Lesson learned about the importance of fuses.

At the Gwangju Poly exhibition site, the floor was sloped, so we built a platform base for safety. Never thought I’d use the table saw skills I learned in woodworking class here.

For the Gwangju exhibition, we even designed with color harmony in mind. Twice as vibrant and beautiful.

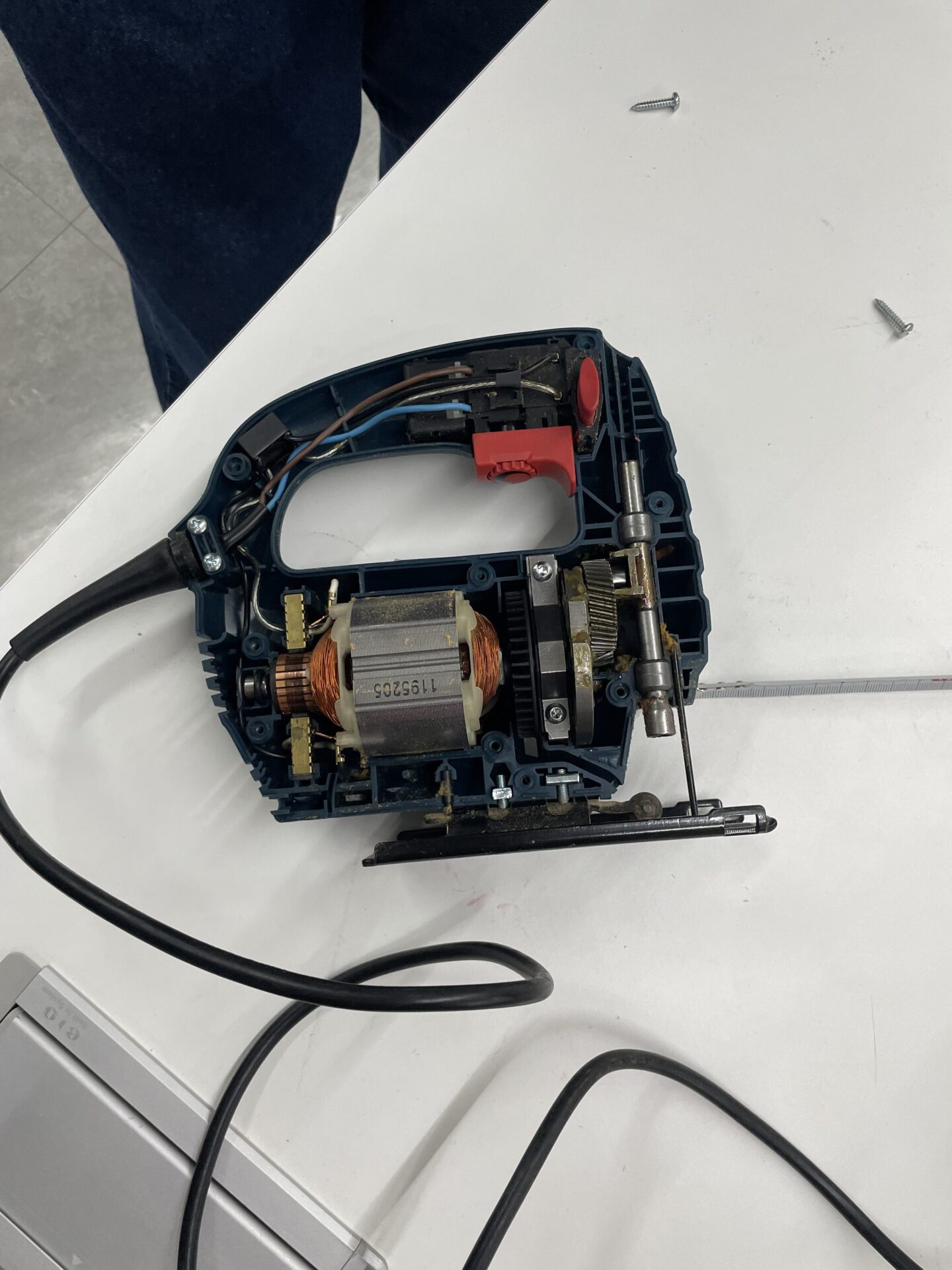

Wait, the jigsaw broke? Open it up again~ Luckily, Mingi fixed it well.

Thanks to that, I got to peek inside the jigsaw.

Building the platform base.

We took over the entire first floor of the architecture building for a couple of days.

We decided to ship the frame and plywood separately, then assemble them on-site. The design had to account for truck size as well as differences between plywood panels and lumber dimensions.

A “nail guide” for on-site use. I remembered using one while assembling an IKEA wardrobe, so I quickly modeled and 3D-printed about ten. This is why having a printer is fun.

Off to Gwangju~ I got to nap comfortably in the back seat—perks of being the junior.

It was early winter. The weather was nice but a little chilly.

After assembling the platform, we applied varnish. Unlike oil, which soaks into wood, varnish forms a thin protective coating on the surface. Thick plastic sheets like the ones we used can be bought in small quantities in Jongno.

On a docent-free day, we visited a famous café in Gwangju—Keo-bok. Maybe because I skipped class to go, it felt extra peaceful. The recharge helped me finish my design deadline strong.

From 2024 onward, Hanyang University won’t be registering teams for UAUS. Like catching the last train—you don’t realize it’s the last until you’re off. Only then do you feel the close call. I gained skills and experience, but best of all, I met amazing people and made lasting friendships. I hope I’ll be able to seize opportunities like this again when they come.

View Other Works

All

Architecture

etc

Furniture

Objet