Round and Round, Further Away

2022, Team Work

Architecture

>Design Studio

The 2022 Cantilever Seesaw Project set as its main challenge the task of supporting 500 ml water bottles placed at the farthest point from the fulcrum. The key was to derive structural integrity from the inherent properties and forms of cardboard, the fixed material of the assignment. The connection angle of each module is determined by the rotation of its perforations, and when assembled at larger angles, the modules form a large central circle. As the circle grows, it helps stabilize the overall center of gravity and allows the horizontal structure to extend farther outward at both ends. Ideally, the larger the circle becomes, the further the horizontal modules can be projected.

Tap the image to open it in full view.

Behind

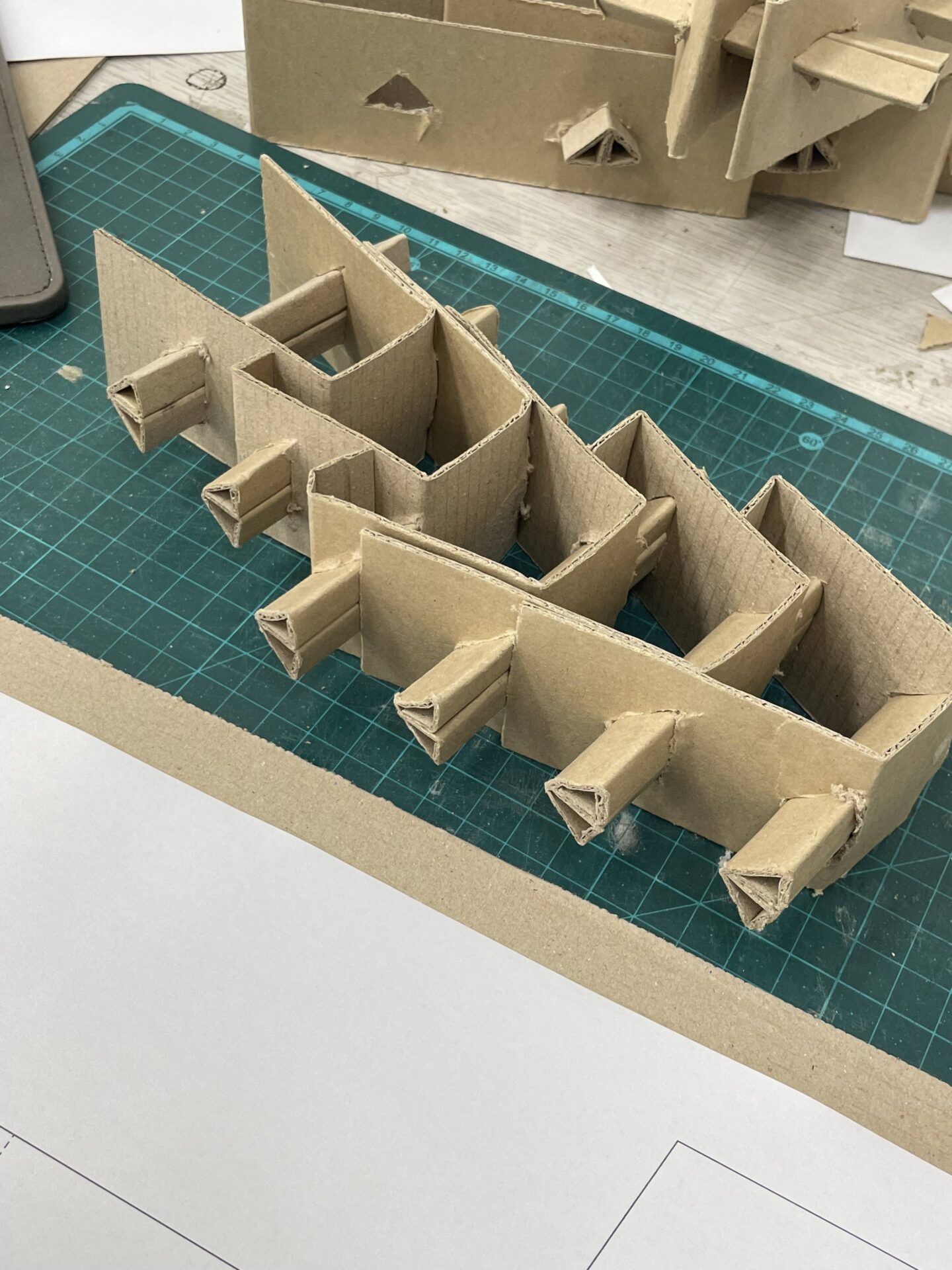

The beginning of the idea. It came about while making various things out of cardboard. The module started with triangular pins and plates slotted together.

A small mockup using A4 paper, repeating columns and plates. It showed potential for expansion and wasn’t hard to assemble.

Tried weaving in various ways using the same method. It gradually developed to connect further and more firmly.

To allow for more formal variety, I standardized the pins and settled on a universal module.

Paper mockup 3.

Made a 1:1 mockup by doubling the number of columns and changing their positions so that length and height could be proportional.

It felt less like a strength test and more like a friendship test.

The triangular pins played a key role in forming each module and also in connecting modules together. When assembling them, I folded the corrugated cardboard considering the grain direction.

I envisioned not just increasing height, but also giving it angles to form curves. After weaving about 15 modules, a curvature began to appear. Once the module test was done, I determined the size and number of circles and completed the design.

To produce in large quantities, I made a kind of jig.

The jig was designed to hold the cut paper in place and make it easy to trace the hole shapes with a pen. At first I thought of cutting directly with a knife through those holes, but that didn’t work well, haha.

Like this. I can’t stand inefficient repetitive work without tools. Once you set up a proper system, things get much easier.

Working with teammates. I cut the base paper, one person did the tracing, another cut the traced patterns. Dividing roles helped each of us gain know-how and reduced working time.

From the bottom up: my role, then Sungho’s, then Jiho’s.

Watching the jig slowly wear out gave me a strange sense of pride. It felt like looking at an old machine in an old factory.

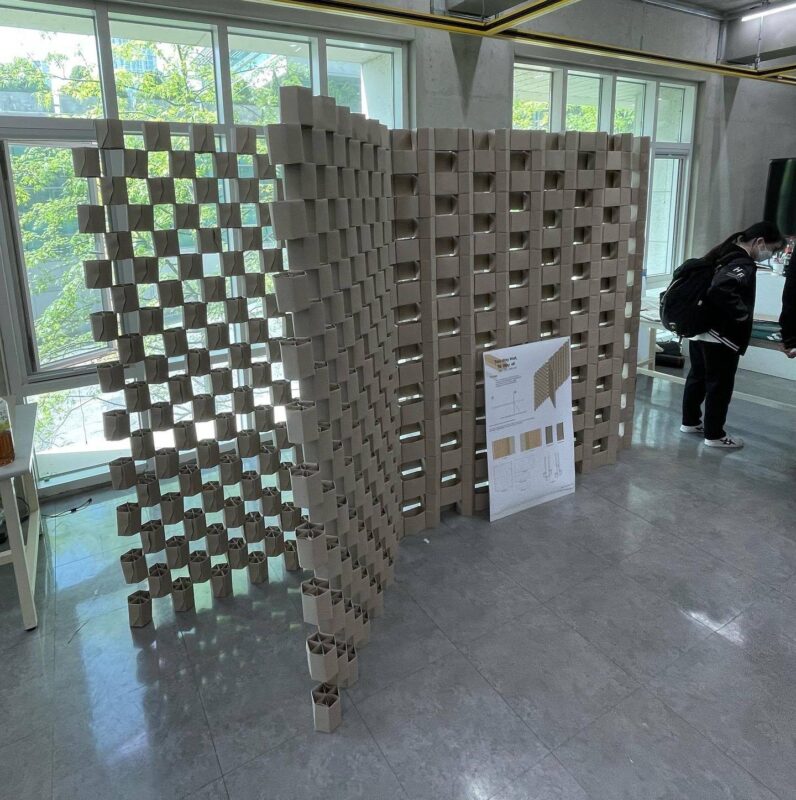

About 40% complete. Some said it looked like deer antlers, others said like a Christmas crown. It was quite large, and friends from other studios came by to check it out.

The circle was complete!!

Photo zone open.

At around 70% completion. Assembling was tougher than expected. Each pin had to hold eight sheets of cardboard, so with force applied, some became loose or tore inside. Later we sorted out the damaged ones and replaced them.

After completion, we even tried flipping it over. The two large cantilever arms sagged under their weight, so we had no choice but to tie transparent fishing line between the cantilever ends and the circle.

Commemorative photo!! By the end of the critique, it couldn’t withstand its own weight and had already become an ellipse. Later, when I took a structural systems class, I often thought back to this project: “I should have done it like this back then…”

View Other Works

All

Architecture

etc

Furniture

Objet